6314-2Z/HC5C3S0WT LRHBJ High Qulity Deep Groove Ball Bearings

Classification :

PRODUCT DETAILS

6314-2Z/HC5C3S0WT LRHBJ High Qulity Deep Groove Ball Bearings

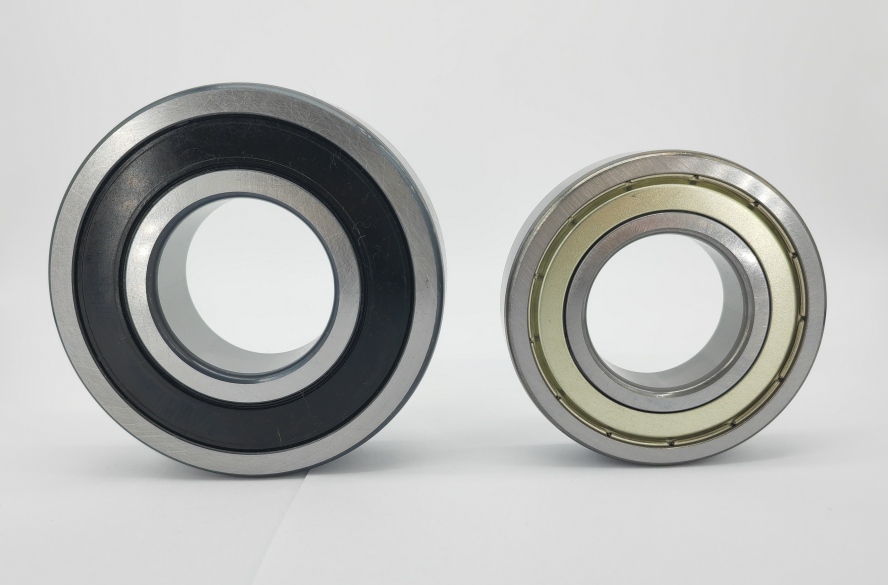

Hybrid Ceramic Deep Groove Ball Bearings with Shields

Hybrid ceramic single row deep groove ball bearings have rings made of bearing steel and rolling elements made of bearing grade silicon nitride, which makes the bearings electrically insulating. Integrated shields can significantly extend bearing life by keeping lubricant in the bearings and contaminants out. Ceramic rolling elements not only provide protection against damage caused by electrical current, but also, compared to bearings of the same size with steel rolling elements, provide improved bearing performance, longer bearing life, higher speed capability, high wear resistance, high bearing stiffness, reduced risk of smearing and false brinelling, and reduced sensitivity to temperature gradients, making them suitable for use in harsh and polluted environments.

Product Description

-Enclosed on both sides with sheet steel protectors;

-HC5- hybrid bearing provides improved electrical insulation properties and is equipped with rolling elements made of silicon nitride;

-S0-Bearing rings are stabilised for temperatures up to +150°C;

-C3-radial internal clearance is larger than normal;

WT-bearing is lubricated with high-temperature grease for a wide temperature range (from -40 to +160°C);

-inner diameter (d) - 70 mm;

-outer diameter (D) -150 mm;

-width (B) -35mm;

-shoulder diameter(d1)-94.95mm;

-Notch diameter (D2) - 129.9 mm;

-Chamfer size (r1,2) - min. 2.1 mm;

-rated load capacity - (dynamic - 104kN), (static - 68kN);

-fatigue strength-2 kN;

-minimum load factor-0.03;

-calculation factor-13.2;

-rated rotation speed-11000 rpm;

-limit rotation speed-6300 rpm;

-weight-2.45kg

Deep Groove Ball Bearings Introduction

Deep groove ball bearing generally consists a pair of rings, a set of cage, a set of steel balls. Its simple structure and easy usability make itself as the most common and most widely used type of bearings. This kind of bearings is mainly used to bear radial load, moreover, it also could withstand a certain amount of axial load. When increasing the radial clearance of bearing, this kind of bearing has properties of angle contact ball bearing to bear a large axial load within a certain range. After assembled on shaft, the deep groove ball bearing can make the axial displacement limit of the shaft or shell within the bearing's axial range. Meanwhile, when the shell hole and shaft (or IR to OR) are relatively tilted (within 8'-16', according to clearance), the bearing could still work as normal, but the service life is reduced.

Limit Of Temperature

The allowable operating temperature of deep groove ball bearings depends on:

Dimensional thermal stability / cages for seals / bearing rings and steel balls.

Sealing element

The allowable operating temperature of the seal depends on the material of the seal:

NBR Butadiene rubber: -40 to +100ºC(-40 to +210F), withstands temperatures up to 120C(250°F) for short periods of time.

FKM: -30ºC to 200C(-20 to 390°F), withstands temperatures up to 230C(445°F) for short periods of time. The highest temperature value of the seal is usually found at the lip of the seal.

Bearing rings and steel balls

The thermal stability of deep groove ball bearings is at least 120C(250*F), and the highest thermal stability of our bearings is 450C.

Cage

The operating temperature of steel, stainless steel, brass or PEEK cages is the same as that of bearing rings and steel balls.

Allowable Speed Of Rotation

The thermal reference mode can be used to quickly assess speed capability. The limit speed is the mechanical limit and should not be exceeded unless the bearing design and application can accommodate higher speeds.

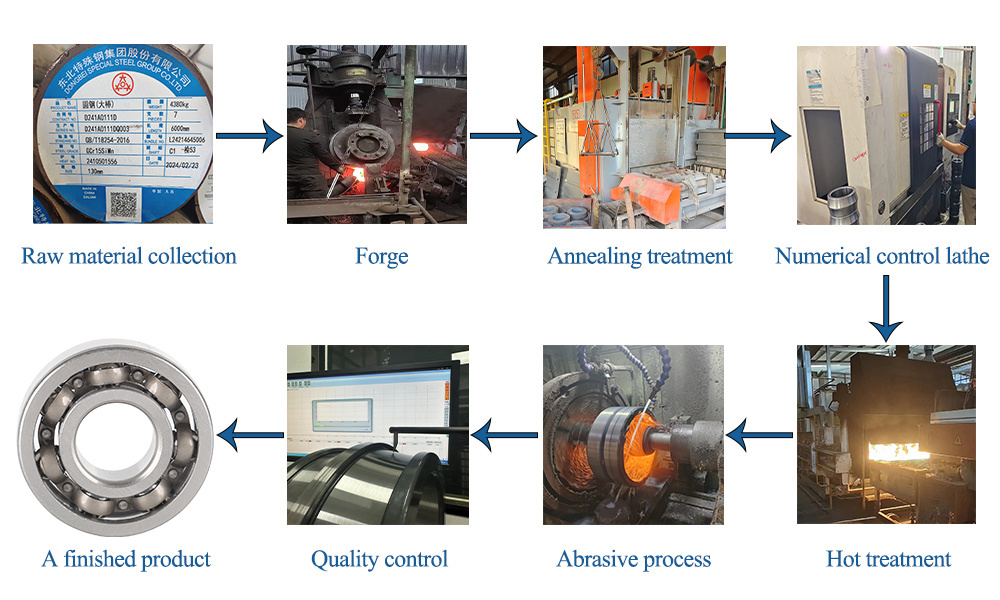

Production Process

Packaging and Transportation

Matters Need Attention

Rolling bearings are precision components, their use must also be appropriate caution. No matter how high-performance bearingsif used improperly, it will not get the expected performance, relevant bearing Cautions below.

1. To keep their surroundings clean bearings

Even tiny invisible dust into the bearing, will increase wear, vibration and noise of the bearing. Bearing and its surroundingattachments should be kept clean. especialy dust and dirt., tools and working environment must be kept clean.

2.When using the installation should carefully

Does not allow a strong punch, does not allow direct bearing percussion hammer is not allowed to pass through the rolling pressure.

3.Using a suitable,accurate installation tool

Try usina a dedicated tool. try to avoid the use of cloth and short fibers such things

4.Prevent bearing corrosion

Direct hand pick bearings, to fully wash hands sweat and coated with high-quality mineral oil before operation.especialy in therainy season and summer mainly rust. However, under the operating conditions of a paricular case, the longer the life the bearinccan be obtained in traditional computing, especially under ight load conditions. These paricular operating condition is, when theroling surface (and the rolling member roling path) is effectively split, and limitations as the lubricant film surface contaminants maylead to damage. In fact, under ideal conditions, the so-called permanent bearing life is possible.

Application Scene

Company Profile

Shandong RHB Bearing Manufacturing Co., Ltd. established in 2008 has become a professional bearing manufacturer with advanced bearing production technology and the most advanced CNC equipment in China.

Our company produces more than 8 million sets of bearings annually, with an output value of more than 90 million RMB. And we adopted first-class production equipment and perfect testing system, we use advanced technical means.

We produce deep groove ball bearings, spherical roller bearings, angular contact ball bearings, cylindrical roller bearings, tapered roller bearings, spherical ball bearings, thrust ball bearings, thrust roller bearings, linear bearings, stainless steel bearings, pillow block bearings, needle roller bearings, non-standard bearings, etc. Bearing precision grades are P0, P6, P5, P4. Our products are widely used in metallurgy, mining, petroleum and chemical industry, coal, cement, paper, wind power, heavy machinery, construction machinery, port machinery and other complete sets of products.

We provide the following services:

1.OEM service, customized bearing size, logo and packaging;

2.CE certificate, EPR certificate and SGS report;

3.One year warranty;

4.Competitive wholesale price;

5.Short delivery time, fast delivery;

6.Free samples for old customers. Free samples of parts bearings for new customers.

Now we are sincerely looking for global general agent. If you choose RHB, you will get good quality bearings, professional service, integrity, and finally we could achieve win-win cooperation!

FAQ

It can be negotiated, we will try our best to meet customers' needs.

Most orders will be shipped within 1-7 days after receiving the payment.

Yes, for one year.

Digital Production, high precision, high speed and low noise.

Reply and answer timely. Provide documents required by customers for customs clearance or sales. 100% after-sales service.

At customers' convenience.

Please send us an inquiry or message in this platform, or you can tell us your phone number, WhatsApp and Wechat. We will contact you as soon as possible and provide more details you need.

FACTORY WORKSHOP

Welcome to Shandong Ruihe Bearing Manufacturing Co., Ltd., your trusted partner for high-quality bearings. With over twenty years of experience in the industry, we are a leading bearing manufacturer with a strong reputation for excellence.

CUSTOMER VISIT

As a professional bearing manufacturer, we offer a wide range of bearing products to meet the diverse needs of our customers. Our products are designed and manufactured to the highest quality standards to ensure reliability and durability. Whether you are looking for standard bearings or custom solutions, we have the expertise and capabilities to meet your requirements.

APPLICATION AREAS

It is mainly used to support the rotating body, reduce friction during movement, and ensure the rotation accuracy of the machine. They are widely used in many fields, machinery manufacturing, automobile industry, electric power industry, aerospace industry, railway transportation. Such as train wheel bearings and train wheel bearings, etc., play an important role in the operation of trains.

PACKING AND SHIPPING

If you are looking for a reliable and professional bearing manufacturer with over twenty years of experience, look no further than Shandong Ruihe Bearing Manufacturing Co., Ltd. Contact us today to learn more about our products and services, and discover how we can help you meet your bearing needs with excellence and precision.

FAQ

"Looking for Reliable Suppliers? We've Got You Covered!"

Q: How is the product packaged?

A: Standard export seaworthy packing with waterproof paper inside and iron outside, secured by fumigated wooden pallets. It can effectively protect products from corrosion and various climate changes during Marine transportation.

Q: Is there quality inspection before loading?

A: Of course, all our products go through strict quality inspection before packing. Those that fail will be destroyed. Customers can also entrust a third party to inspect the products before loading.

Q: What are the loading ports?

A: In general, we ship the goods from Shanghai, Tianjin, Qingdao and Ningbo ports. You can designate other ports according to your needs.

Q:Can you deliver the goods on time?

A: Yes, we guarantee the best quality products and punctual delivery. Integrity is the tenet of our company.

Q: Can we take some samples? Any fees?

A: Yes, we can provide samples free of charge, but we don't pay for shipping. If you place an order after confirming the sample, we will refund your delivery fee or deduct it from the order amount.

Q: Can I visit your factory?

A: Of course. We welcome customers from all over the world to visit our factory.

Q: Are you a trading company or a manufacturer?

A: We are a professional bearing production company, but also a very professional bearing trading company

RELATED PRODUCTS

GET A FREE QUOTE